Amphitec Vortex

Vehicle Specifications

- Type: Amphitec Vacuum Equipment

- Chassis Manufacturer: Mercedes-Benz

- Chassis Configuration: Arocs 5 3253L StreamSpace 8x4x4, right-hand drive, including MirrorCam, audible left turn warming with side scanners, 4 way camera system with DVR recording, 1.2 metre LED roof-mounted blaze bar

- Suction Boom: Amphitec 10-inch boom, operated from radio remote controlled, articulated suction hose carrier 6000

- Filter Chamber: 10515 Filter Chamber Execution 1450mm. The main filter separates particles from the airflow. This filter contains widely spaced filter frames covered by high-quality polyester needle felt filter containing 30 bags with a total filter surface of 33m2.

- Blowing System: Amphitec blowing system - The blowing feature allows for the discharge of free flowing dry materials through a hose and can include discharge into a silo or ballast on a flat roof. After filling and subsequent tipping of the tank, products will flow into the blowing outlet. Product is pneumatically transported through the blowing hose, using airflow and pressure supplied by the vacuum pump by means of an internal aeration and venturi system.

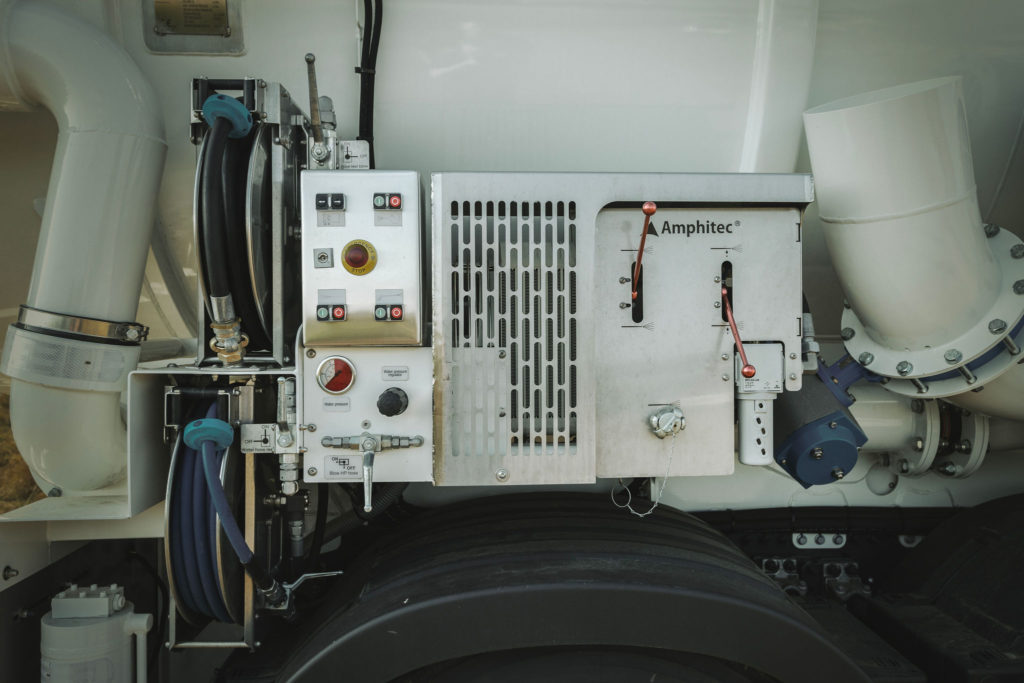

- High Pressure Pump: Maximum waterflow of 50L/min and a maximum pressure of 120 bar. The installed industrial high-pressure pump is driven by a hydraulic PTO. A manually operated hose storage reel is installed at the rear side of the chassis and is equipped with 20 meter ½“ high-pressure hose. An air pressure connection is located next to the hose reel to be able to empty the hoses to prevent frost damage. Water tank is integrated in the front partition of the tank, approx. 500L. (This option is exclusively possible with a closed filter chamber configuration.)

Gallery